In today’s fast-paced and technology-driven world, the demand for efficient automation solutions is on the rise. Programmable control panels are central to the automation infrastructure, providing advanced control and monitoring of various systems across industries. From manufacturing facilities to smart homes, these programmable panels empower users to streamline processes, improve productivity, and reduce manual errors. This guide delves into the advantages of programmable control panels, their applications, and tips on implementing them for seamless automation.

What Are Programmable Control Panels?

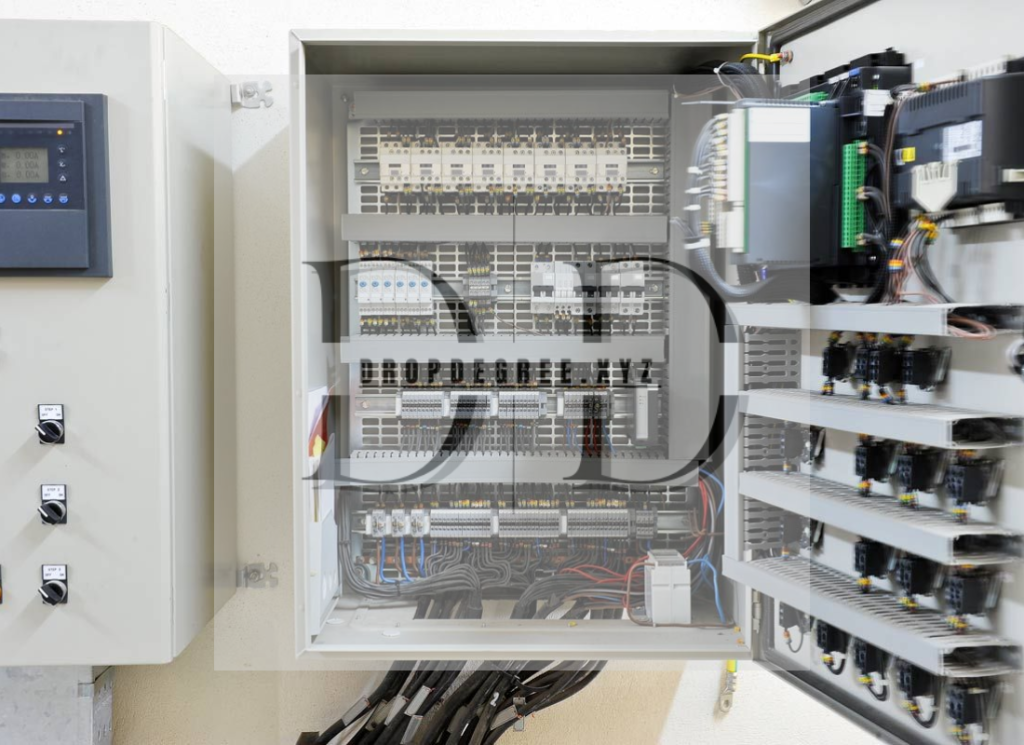

Programmable control panels are interfaces that allow users to control, monitor, and automate systems by programming specific tasks, schedules, and sequences of actions. Typically, they consist of hardware and software components, including controllers, relays, sensors, and displays. Users can program these panels to execute specific functions, such as regulating temperatures, controlling machinery, managing lighting, and more. These control panels bring flexibility and customization to processes, ensuring that different components work together in harmony.

Key Features of Programmable Control Panels

- Customization: Program panels to perform specific tasks according to the unique requirements of the application.

- Real-Time Monitoring: Track data and metrics in real time, allowing for swift adjustments as needed.

- Remote Access: Many panels offer remote access, allowing for control from various locations.

- Interconnectivity: Integrate with other smart devices or systems for a cohesive automation network.

Benefits of Programmable Control Panels for Automation

Programmable control panels are revolutionizing automation, offering numerous benefits to businesses and homes alike. Here’s why these systems are essential for optimizing operations:

1. Enhanced Efficiency

Programmable control panels can automate repetitive tasks, which frees up time for employees to focus on more complex responsibilities. For example, in manufacturing, panels can control assembly lines, ensuring each stage of production operates smoothly and without human intervention. By automating essential functions, businesses can eliminate delays and improve overall productivity.

2. Improved Accuracy and Precision

Manual control is prone to human error, especially in environments where quick adjustments are needed. Programmable panels reduce the chance of mistakes by executing programmed commands precisely and consistently. This increased accuracy is crucial in industries such as pharmaceuticals, food production, and electronics, where even minor errors can lead to costly repercussions.

3. Energy Efficiency

Automated control panels allow users to optimize energy use, an increasingly vital consideration in both industrial and residential settings. For instance, by programming control panels to adjust lighting, HVAC systems, and machinery operation times, users can reduce energy consumption during non-peak hours. This not only minimizes energy costs but also contributes to sustainability efforts.

4. Scalability for Growing Needs

As businesses grow, so do their operational needs. Programmable control panels are flexible and scalable, allowing for easy adjustments as new equipment, systems, or processes are added. For instance, if a manufacturing facility expands, the control panels can be reprogrammed to accommodate additional machinery or workstations without extensive system overhauls.

5. Real-Time Data Collection and Analysis

Programmable control panels often come with data tracking capabilities, enabling users to monitor various metrics in real time. This data provides valuable insights into system performance, helping users to identify patterns, inefficiencies, and potential issues before they escalate. For example, in HVAC systems, control panels can monitor temperature fluctuations, energy usage, and filter conditions, ensuring optimal performance and timely maintenance.

6. Remote Access and Control

Many modern control panels offer remote access, allowing users to monitor and control systems from virtually anywhere. This is especially useful for facilities that require constant oversight, such as warehouses, production floors, or data centers. Remote access capabilities also make troubleshooting more efficient, as technicians can identify and address issues without being on-site.

7. Cost Savings

Automating processes with programmable control panels can lead to significant cost savings. Reduced energy consumption, minimized downtime, and improved accuracy all contribute to lower operational costs. Furthermore, automation allows businesses to operate efficiently with a smaller workforce, reducing payroll expenses over time.

Key Applications of Programmable Control Panels

Programmable control panels have applications across a wide range of industries and environments. Here are some common uses:

1. Industrial and Manufacturing Automation

In industrial settings, programmable control panels are used to control complex machinery and manage production lines. They can be programmed to adjust machine settings, manage quality control, and schedule maintenance. This automation streamlines the production process, minimizes manual intervention, and enhances overall efficiency.

2. Building and Facility Management

From controlling lighting and HVAC systems to managing security and access control, programmable panels are central to building automation. Facility managers can schedule lights to turn off after work hours, set HVAC systems to adjust based on occupancy, and monitor security cameras in real time. This level of control ensures optimal energy use, enhanced security, and comfort for occupants.

3. Smart Homes

In residential settings, programmable control panels make it easy to create a smart home environment. Users can set schedules for lighting, control smart thermostats, manage home security, and even integrate voice-activated assistants for hands-free control. This enhances convenience, comfort, and security in the home.

4. Energy Management

Control panels are essential in energy management systems, especially for businesses looking to optimize energy use. Panels can control solar energy systems, monitor power usage in real-time, and manage load distribution to reduce peak demand charges.

5. Healthcare and Pharmaceuticals

Automation is critical in healthcare and pharmaceutical industries, where precision and consistency are paramount. Programmable control panels are used to control lab equipment, monitor refrigeration units, and manage air quality systems. This automation helps maintain strict regulatory standards and improves patient safety.

6. Agriculture

In agriculture, programmable control panels are used in various ways, such as controlling irrigation systems, monitoring soil conditions, and regulating greenhouse environments. Automated systems help ensure optimal growing conditions and reduce water and energy waste.

How to Implement Programmable Control Panels for Optimal Efficiency

Implementing programmable control panels effectively requires careful planning and consideration of specific needs. Here’s a step-by-step guide to ensure a successful implementation:

1. Identify Your Automation Goals

Define what you want to achieve with automation, whether it’s reducing energy costs, improving safety, or increasing production efficiency. Clear goals will help guide the programming of your control panel to meet specific requirements.

2. Choose the Right Control Panel

Consider the capabilities, compatibility, and scalability of the control panel. Ensure that it can integrate with your existing systems and supports future expansion if needed. Look for models that offer remote access, real-time monitoring, and data tracking for added value.

3. Integrate with Existing Systems

Programmable control panels should integrate smoothly with other systems in your setup. This may involve connecting to sensors, devices, and controllers in the network. It’s essential to verify compatibility and plan for smooth communication between the control panel and all integrated components.

4. Program the Panel for Efficiency

Programming the panel according to specific tasks is crucial. Collaborate with a technician or engineer to create customized commands and sequences that align with your goals. In a smart building, for example, you might program the HVAC system to adjust temperatures based on occupancy levels and set lights to automatically turn off in unoccupied areas.

5. Train Personnel

For maximum efficiency, ensure that employees or residents understand how to use the control panel effectively. Training is especially important in industrial environments, where improper use could disrupt operations or compromise safety.

6. Monitor and Adjust

After implementation, monitor the system regularly to ensure it’s functioning as intended. Analyze data collected by the control panel to make adjustments, optimize settings, and address any issues promptly. Periodic updates and recalibration may be necessary as operational needs evolve.

Choosing the Right Programmable Control Panel

Selecting a control panel depends on several factors, including budget, functionality, and intended applications. Here are some top considerations:

- Budget: Determine how much you’re willing to spend. Higher-end models offer more features but come at a premium.

- Scalability: Choose a panel that can grow with your needs.

- Integration: Look for a panel that can easily integrate with existing equipment and other automated systems.

- Remote Access: For added convenience, opt for models that offer remote access and control.

Some reliable brands in programmable control panels include Schneider Electric, Siemens, Rockwell Automation, and Honeywell. Researching these brands can provide a starting point for selecting a panel that meets your unique requirements.

Conclusion

Programmable control panels are powerful tools that enhance efficiency, accuracy, and flexibility across a variety of applications. From industrial automation to smart home setups, these panels streamline operations, reduce costs, and create a more sustainable and controlled environment. By investing in a programmable control panel and implementing it strategically, businesses and homeowners can reap significant benefits and embrace the future of automation with ease.