Introduction: Understanding DC Electric Motors

DC electric motors are pivotal in today’s technology landscape, offering a reliable, adaptable power source across numerous applications. Whether in electric vehicles, industrial machinery, or household appliances, DC motors are integral to the operation of systems that demand precise speed and torque control. Known for their high efficiency, responsive speed regulation, and durable construction, DC motors are a top choice for engineers and designers focused on optimizing performance. As industries continue to innovate, DC electric motors are evolving to meet the needs of emerging technologies, making them essential for achieving greater efficiency, productivity, and sustainability.

This article provides a comprehensive look into the mechanics of DC electric motors, from their core components to the types of DC motors available, such as series, shunt, and permanent magnet models. Additionally, we’ll explore their benefits, including energy efficiency and enhanced speed control, along with practical applications in various fields. Finally, we’ll examine the future of DC electric motors, highlighting how advancements in materials and IoT integration are driving their evolution in an increasingly technology-driven world. By understanding the fundamentals and capabilities of DC electric motors, industry professionals and hobbyists alike can make informed choices for powering modern applications effectively and sustainably.

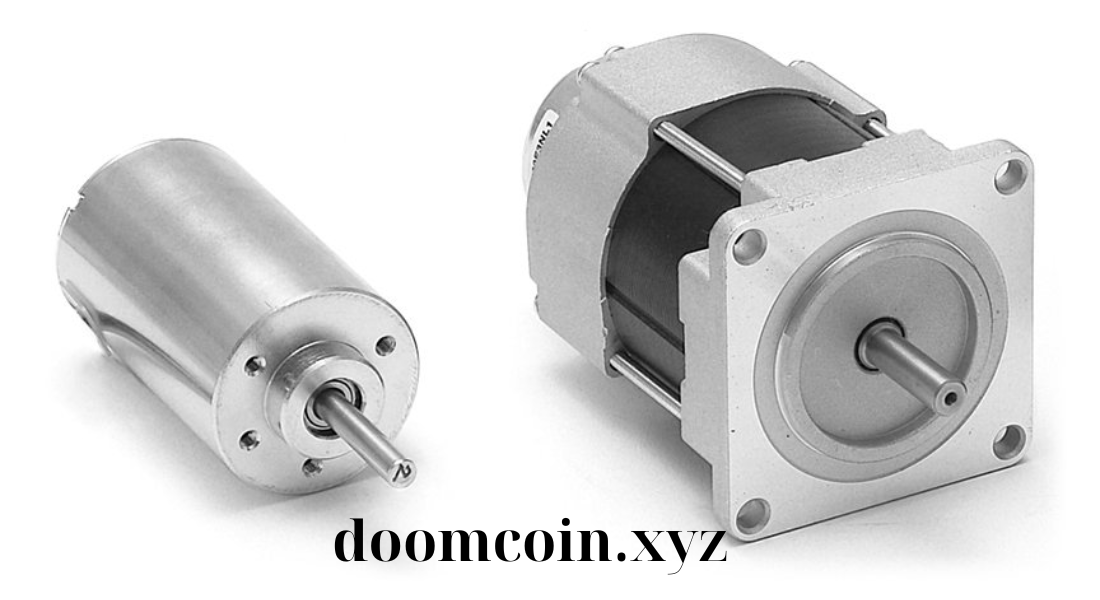

What Are DC Electric Motors?

A DC electric motor is a machine that converts direct current electrical energy into mechanical energy. The motor operates by leveraging the interaction between magnetic fields and electric current within its windings to generate movement. This reliable technology has been instrumental in numerous sectors, creating opportunities for optimized power use and controlled performance.

Types of DC Electric Motors

DC electric motors come in various forms, each suited to specific applications based on their unique properties. Understanding these types is essential for selecting the right motor for a given use:

- Series DC Motors:

Known for their high starting torque, series DC motors are typically used in applications requiring a powerful start, such as cranes and elevators. - Shunt DC Motors:

Featuring a stable speed characteristic, shunt motors are commonly used in applications requiring consistent speed, like fans and blowers. - Compound DC Motors:

Combining the properties of series and shunt motors, compound motors offer high starting torque and stable speed, making them ideal for applications like conveyor belts and printing presses. - Permanent Magnet DC Motors (PMDC):

PMDC motors are lightweight and energy-efficient, commonly used in portable devices, automotive applications, and even robotics.

Key Components of DC Electric Motors

To fully appreciate how DC electric motors work, it’s essential to understand their main components:

- Stator and Rotor: The stationary stator creates a magnetic field, while the rotor, connected to the motor shaft, rotates to produce motion.

- Armature Windings: These windings, located on the rotor, conduct current and are essential for generating torque.

- Commutator and Brushes: These parts help transfer current from the power source to the rotating armature, ensuring consistent energy flow and directionality in the motor’s operation.

Advantages of Using DC Electric Motors

DC electric motors offer a range of benefits, making them a top choice for industries seeking reliable, adaptable power solutions.

- Precise Speed Control:

DC motors provide superior speed control, allowing for adjustments to torque and speed. This feature is valuable in applications requiring accuracy, such as in conveyor systems. - High Starting Torque:

The ability to deliver significant starting torque makes DC motors ideal for applications where load demand varies, such as in elevators and trains. - Energy Efficiency:

DC motors are known for their efficient energy usage, reducing overall energy consumption and contributing to lower operating costs. - Simpler Control Mechanisms:

Compared to AC motors, DC motors often have simpler control mechanisms, which can lower system complexity and maintenance costs.

Applications of DC Electric Motors

The versatility of DC electric motors makes them applicable in many areas. Here are some common uses:

- Electric Vehicles (EVs):

DC motors are widely used in EVs for their efficient speed control and energy efficiency. Permanent magnet DC motors are popular choices for electric cars and hybrid vehicles. - Industrial Automation:

From conveyor belts to robotic arms, DC motors provide reliable power for machinery in manufacturing and logistics. - Home Appliances:

Smaller DC motors are frequently found in home appliances such as fans, blenders, and vacuum cleaners, where efficient power and speed control are essential. - Medical Equipment:

DC motors are integral to medical devices like imaging systems, diagnostic machines, and surgical tools, offering precise control needed in healthcare. - Renewable Energy Systems:

Used in wind and solar power installations, DC motors convert natural energy sources into usable electrical energy, supporting sustainable energy solutions.

Maintenance and Care of DC Electric Motors

Maintaining a DC electric motor ensures it operates efficiently and lasts longer. Here are some crucial maintenance steps:

- Regular Inspection of Brushes and Commutators:

Worn brushes or a damaged commutator can hinder performance. Regularly inspecting these parts is vital to prevent disruptions in motor function. - Lubrication of Bearings:

Bearings reduce friction and wear in the motor. Applying the right lubrication at appropriate intervals minimizes wear and enhances efficiency. - Cleaning:

Dust and debris can accumulate within the motor, affecting its performance. Periodic cleaning can prevent overheating and ensure optimal operation. - Temperature Monitoring:

Overheating is a significant issue in motor performance. Monitoring temperature levels can prevent damage due to excessive heat, extending the motor’s lifespan.

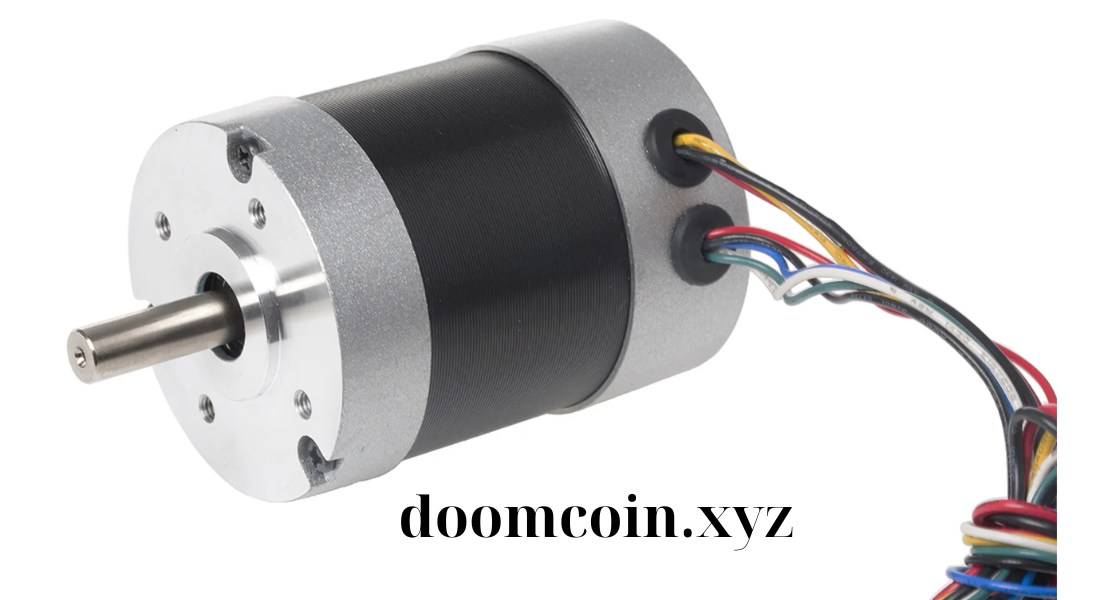

Future of DC Electric Motors

DC electric motors continue to evolve, incorporating advancements in materials and digital technology. Emerging trends indicate a future with even more energy-efficient, compact, and powerful motors. Innovations such as brushless DC motors offer increased reliability and reduced maintenance, making them attractive for new applications.

- Integration with IoT:

With the rise of IoT, smart DC motors capable of real-time monitoring and control are gaining traction. These motors can self-diagnose issues and optimize performance, proving beneficial in manufacturing and transportation. - Use in Green Technology:

As industries shift toward sustainable practices, DC electric motors are central to renewable energy projects. Motors used in solar panels, wind turbines, and EVs are expected to increase as demand for green technology rises. - Advancements in Materials:

New materials, like carbon nanotubes and advanced ceramics, are being explored to improve motor efficiency and reduce weight, paving the way for lighter, faster, and more energy-efficient motors. - Enhanced Battery Compatibility:

For applications reliant on battery power, such as EVs, advancements in battery technology will directly benefit DC motors, enabling longer operating times and reduced charging frequency.

Conclusion: Choosing DC Electric Motors for Versatile Power

DC electric motors stand out for their versatility, reliability, and adaptability across diverse applications. Their efficiency and ability to deliver precise speed control make them ideal for industries prioritizing optimized performance. As technology advances, DC motors will remain integral in shaping sustainable and innovative solutions across sectors.

DC electric motors will continue evolving alongside the demand for efficient power solutions, from industrial automation to green energy and beyond. Selecting the appropriate DC motor type, maintaining it well, and staying informed about industry advancements can maximize the benefits of this enduring technology.