Electric Motor Repair: A Comprehensive Guide for Optimal Performance

Electric motors are integral components in various industries, powering everything from household appliances to large-scale machinery. When an electric motor malfunctions, it can disrupt operations, leading to costly downtime and repairs. Understanding the basics of electric motor repair is essential for both maintenance personnel and operators. This comprehensive guide will walk you through the process of diagnosing and repairing electric motors, offering valuable insights into troubleshooting techniques, repair steps, and when it’s time to seek professional help.

1. Understanding Electric Motors

Before diving into the repair process, it’s crucial to have a basic understanding of how electric motors work. Electric motors convert electrical energy into mechanical energy through electromagnetic principles. They consist of key components such as the stator, rotor, bearings, and windings. The stator produces a magnetic field, which interacts with the rotor to generate rotational motion.

Common types of electric motors include:

- AC Motors: These motors operate on alternating current and are widely used in industrial and commercial applications.

- DC Motors: Powered by direct current, DC motors are typically found in smaller applications and offer precise control over speed and torque.

- Brushless Motors: These motors are more efficient and require less maintenance, often used in robotics and computer components.

Understanding these components and their functions helps diagnose common issues during electric motor repair.

2. Common Causes of Electric Motor Failure

Several factors can lead to electric motor failure, and identifying the root cause is the first step toward effective repair. Common causes include:

- Overheating: Excessive heat is a primary cause of motor failure. It can be due to poor ventilation, overloaded circuits, or faulty windings.

- Electrical Failures: Issues such as short circuits, power surges, or incorrect voltage can damage the motor’s electrical components.

- Mechanical Failures: Worn bearings, damaged shafts, or misalignment can cause mechanical issues that affect motor performance.

- Contamination: Dust, dirt, and moisture can interfere with the motor’s internal components, leading to failures.

- Improper Maintenance: Lack of routine maintenance or improper lubrication can contribute to motor wear and eventual failure.

Recognizing these issues early on can help minimize downtime and reduce repair costs.

3. Electric Motor Repair Process

When an electric motor stops working, the first step is to identify the problem. Follow these steps for efficient motor repair:

Step 1: Turn Off Power and Disconnect the Motor

Safety should always be the top priority. Disconnect the motor from its power source to avoid any electrical hazards. Ensure that the area is secure and that no live wires are exposed.

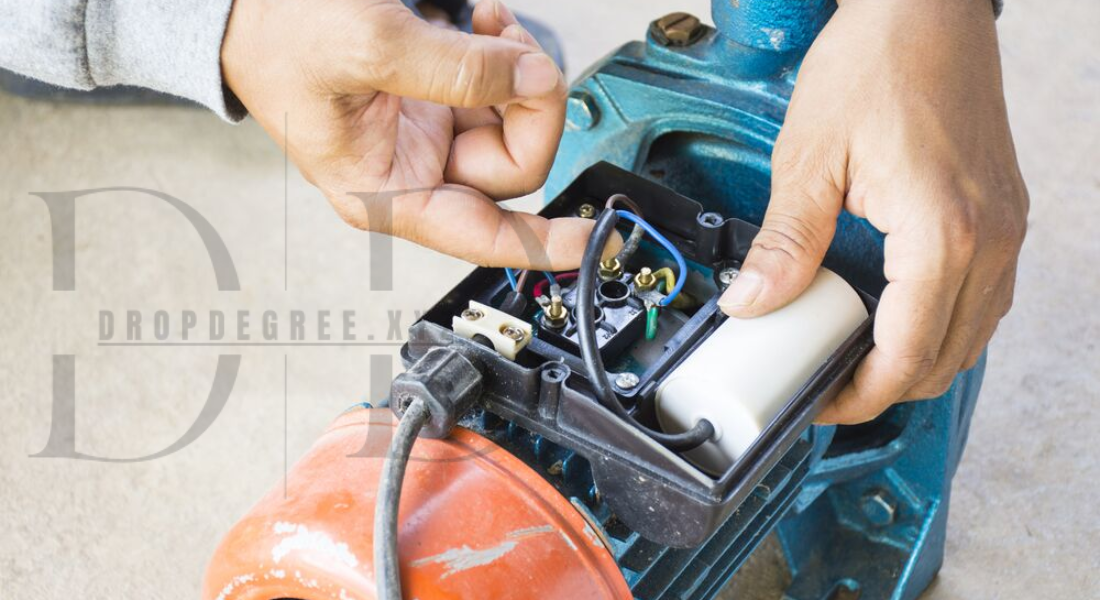

Step 2: Inspect the Motor

Visually inspect the motor for any obvious signs of damage, such as burnt components, oil leaks, or visible wear on the bearings. Look for any loose connections or broken wires. This inspection can provide valuable clues about the nature of the problem.

Step 3: Test the Motor with a Multimeter

Using a multimeter, test the motor’s windings for continuity and resistance. A lack of continuity or abnormal resistance readings may indicate issues with the stator or rotor. Additionally, test for any electrical shorts that could have caused the motor failure.

Step 4: Examine Bearings and Mechanical Components

Check the motor’s bearings for any signs of wear or damage. If the bearings are worn out, they may need to be replaced. Similarly, inspect the motor shaft and other moving parts for misalignment or damage.

Step 5: Clean the Motor

Dirt and debris can hinder motor performance. Use compressed air or a soft brush to clean the motor’s external surfaces, paying special attention to ventilation openings and cooling fans. Remove any debris from the rotor and stator windings, ensuring that the motor operates at peak efficiency.

Step 6: Lubricate Moving Parts

If the motor includes bearings or other moving components, apply appropriate lubrication to reduce friction and prevent further damage. Be sure to use the correct type of lubricant as recommended by the motor manufacturer.

Step 7: Reassemble and Test the Motor

Once you’ve completed the inspection, cleaning, and lubrication, reassemble the motor and reconnect it to the power supply. Test the motor to ensure it runs smoothly and without unusual noises or vibrations. Monitor the motor for any signs of overheating or other issues.

4. Troubleshooting Common Electric Motor Problems

Even with proper maintenance, electric motors can experience issues. Here’s how to troubleshoot common electric motor problems:

- Motor Not Starting: If the motor doesn’t start, check the power supply and ensure that all electrical connections are secure. Inspect the motor’s start capacitor and thermal overload protection device to ensure they are functioning correctly.

- Overheating Motor: If the motor is overheating, it could be due to overloading, insufficient ventilation, or faulty bearings. Ensure the motor is not overloaded and that it has adequate airflow for cooling.

- Unusual Noises or Vibrations: Strange noises, such as grinding or squealing, could indicate worn bearings or an unbalanced rotor. These issues should be addressed promptly to avoid further damage.

- Intermittent Operation: If the motor runs intermittently, check the electrical connections for loose wires or damaged components. This issue may also result from a faulty motor capacitor.

5. Electric Motor Maintenance Tips

Preventive maintenance is the key to extending the life of electric motors and reducing the frequency of repairs. Follow these tips to ensure your motors remain in optimal condition:

- Regular Cleaning: Dust and dirt buildup can impair motor function. Clean the motor regularly to maintain airflow and prevent overheating.

- Lubricate Bearings: Lubricate bearings and moving parts as recommended by the manufacturer to reduce wear and tear.

- Monitor Motor Temperature: Keep an eye on the motor’s temperature. Excessive heat is a sign of underlying issues that need to be addressed.

- Check Electrical Connections: Loose or corroded electrical connections can cause motor failure. Ensure that all connections are tight and free from corrosion.

- Inspect for Vibration: Regularly check for unusual vibrations or noises, as these may signal mechanical problems within the motor.

6. When to Seek Professional Electric Motor Repair Services

While many motor repair tasks can be completed in-house, there are situations where professional help is required. Consider calling a professional if:

- You lack the proper tools or expertise to perform a thorough diagnosis and repair.

- The motor requires specialized parts that are difficult to obtain or replace.

- You encounter a complex electrical fault that requires advanced troubleshooting.

- The motor is part of a critical system where failure could result in significant downtime or safety risks.

Professional repair services can help ensure that the motor is properly repaired and restored to optimal performance. They have the tools, expertise, and experience to handle complex motor issues safely and efficiently.

7. Conclusion

Electric motor repair is an essential skill for maintaining the performance and longevity of motors across various industries. By understanding common causes of failure, following proper repair procedures, and implementing regular maintenance practices, you can keep your electric motors running smoothly. Whether you’re troubleshooting a minor issue or performing a more in-depth repair, a proactive approach to electric motor maintenance can help prevent costly repairs and downtime. When in doubt, don’t hesitate to seek professional assistance to ensure your motor is repaired correctly and safely.

By following this expert guide on electric motor repair, you can confidently diagnose issues, perform repairs, and keep your equipment in top working condition. Whether for industrial machinery or everyday appliances, mastering the basics of motor repair is an invaluable skill that can save time, money, and frustration in the long run.