Introduction

Electric motor efficiency is a critical factor that determines how effectively an electric motor converts electrical energy into mechanical energy. With the rising importance of energy conservation, understanding and optimizing the efficiency of electric motors has become more crucial than ever. This guide explores what electric motor efficiency is, why it matters, and how to improve it for better performance, lower operational costs, and a greener environment.

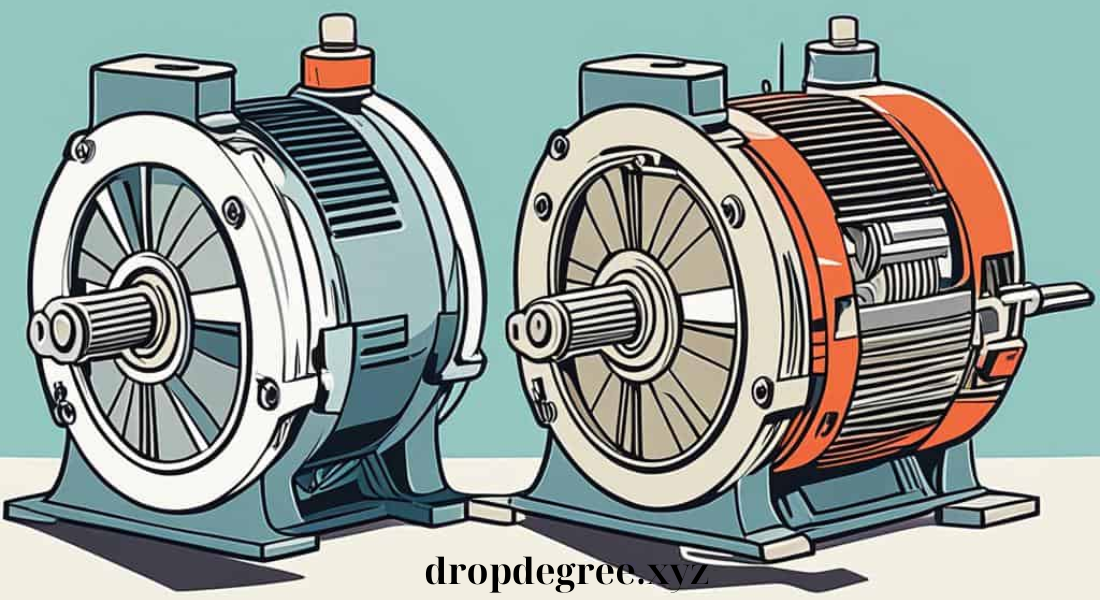

What is Electric Motor Efficiency?

Electric motor efficiency refers to the ratio of the mechanical power output to the electrical power input. It indicates how much of the electrical energy consumed by the motor is actually converted into useful mechanical work, with the rest being lost as heat and other forms of waste. The higher the efficiency, the less energy is wasted, making the motor more cost-effective and environmentally friendly.

Key Points:

- Efficiency = (Mechanical Power Output / Electrical Power Input) x 100%

- High efficiency reduces energy waste and operational costs

- Vital for applications in industries, commercial use, and residential settings

Why is Electric Motor Efficiency Important?

The importance of electric motor efficiency cannot be overstated, as it has a direct impact on energy consumption, operational costs, and environmental footprint. Motors are widely used in various sectors, including manufacturing, HVAC systems, electric vehicles, and home appliances. Improving efficiency can lead to significant energy savings, reduced carbon emissions, and longer equipment lifespan.

Benefits of High Efficiency:

- Reduced energy bills due to lower power consumption

- Minimized greenhouse gas emissions, contributing to sustainability

- Extended motor lifespan with less heat generation and wear

- Enhanced overall system performance and reliability

Factors Affecting Electric Motor Efficiency

Several factors influence the electric motor efficiency, and understanding them is key to making informed choices. Below are some critical factors:

- Motor Size and Design: Larger motors tend to be more efficient due to lower losses. Design aspects like winding configuration and core materials also play a role.

- Load Conditions: Operating a motor near its rated load typically results in better efficiency. Motors running at very low or high loads experience reduced efficiency.

- Power Quality: Voltage fluctuations, harmonics, and poor power factor can negatively impact motor efficiency, leading to increased energy consumption.

- Cooling Systems: Effective cooling reduces heat loss, enhancing electric motor efficiency. Inefficient cooling leads to higher temperatures and decreased performance.

- Maintenance and Lubrication: Regular maintenance and proper lubrication reduce mechanical friction, improving overall efficiency.

Key Takeaway: Choosing the right motor size, maintaining optimal load, and ensuring high power quality can significantly enhance efficiency.

How to Improve Electric Motor Efficiency

Boosting the electric motor efficiency involves a combination of correct motor selection, proper maintenance, and the implementation of energy-efficient practices. Below are some actionable strategies:

1. Select the Right Motor for the Application

Selecting the appropriate motor for the specific task is the first step in maximizing efficiency. This includes considering the motor’s size, type, and efficiency rating. Motors with a higher efficiency rating, such as Premium Efficiency motors, often have a higher initial cost but provide long-term savings in energy consumption.

Tips for Selection:

- Choose motors with higher efficiency ratings (Premium Efficiency or IE3)

- Avoid oversizing motors to match load requirements

- Consider variable-speed motors for applications with fluctuating loads

2. Regular Maintenance and Monitoring

Routine maintenance is crucial for maintaining electric motor efficiency. This includes inspecting and replacing worn-out components, lubricating moving parts, and monitoring motor performance. Implementing a predictive maintenance schedule can prevent unexpected failures and maintain peak efficiency.

Maintenance Practices:

- Inspect bearings and replace if necessary

- Keep cooling systems clean and free of debris

- Monitor for vibrations and unusual noises

- Use thermal imaging to detect overheating issues

3. Optimize Load Management

Operating motors at their optimal load is essential for maintaining high efficiency. Motors running at very low loads waste energy, while those running above their rated capacity can overheat and degrade faster. Proper load management can significantly boost electric motor efficiency.

Load Optimization Tips:

- Use variable frequency drives (VFDs) for adjustable load conditions

- Ensure that motors are running within 70-100% of their rated capacity

- Implement load balancing techniques to distribute energy use evenly

4. Upgrade to Energy-Efficient Motors

One of the most effective ways to improve electric motor efficiency is to upgrade to energy-efficient models. Modern energy-efficient motors are designed with advanced materials and technologies to reduce energy loss. Though they may have a higher upfront cost, the savings in energy bills make them a cost-effective investment.

Benefits of Upgrading:

- Significant energy savings over time

- Lower operational costs

- Reduced carbon footprint and environmental impact

- Eligibility for energy efficiency incentives and rebates

Technologies Enhancing Electric Motor Efficiency

Technological advancements have played a significant role in improving electric motor efficiency. Some key technologies include:

1. Variable Frequency Drives (VFDs)

VFDs are used to control the speed and torque of electric motors by adjusting the motor’s input voltage and frequency. This technology helps in maintaining efficiency even under varying load conditions, reducing energy consumption and improving motor lifespan.

Advantages of VFDs:

- Enhanced control over motor speed

- Reduced energy consumption at partial loads

- Lower mechanical stress and maintenance needs

2. Permanent Magnet Motors

Permanent magnet motors utilize strong magnets instead of windings, reducing energy losses and enhancing electric motor efficiency. These motors are often used in high-efficiency applications like electric vehicles and HVAC systems.

Benefits:

- Higher efficiency compared to traditional induction motors

- Compact and lightweight design

- Lower maintenance requirements

3. Smart Sensors and IoT

Smart sensors and IoT technologies are increasingly used to monitor and optimize the performance of electric motors. These sensors provide real-time data on various parameters, such as temperature, vibration, and power consumption, enabling predictive maintenance and fine-tuning for maximum efficiency.

Smart Technology Advantages:

- Real-time performance monitoring

- Early detection of issues to prevent breakdowns

- Data-driven optimization for better efficiency

Measuring and Monitoring Electric Motor Efficiency

Understanding how to measure and monitor electric motor efficiency is crucial for maintaining peak performance. Tools like power analyzers, thermal cameras, and vibration sensors can help identify inefficiencies and areas for improvement. Regular efficiency testing allows you to detect anomalies early and take corrective actions to maintain optimal efficiency.

Monitoring Tools:

- Power analyzers for checking electrical input and output

- Thermal cameras for detecting hot spots and overheating

- Vibration sensors for identifying mechanical issues

Conclusion: The Benefits of Optimizing Electric Motor Efficiency

Improving electric motor efficiency is not just about saving on energy bills; it’s about enhancing performance, extending equipment lifespan, and contributing to environmental sustainability. By understanding the factors that impact efficiency and employing the right strategies, businesses and individuals can achieve better energy management and cost savings. From proper motor selection and regular maintenance to leveraging advanced technologies, there are numerous ways to make your electric motors work smarter, not harder.

In conclusion, optimizing electric motor efficiency is a proactive step towards a more efficient, cost-effective, and eco-friendly future. Whether you’re managing a large industrial facility or using motors for personal projects, the benefits of maximizing efficiency are far-reaching, making it a worthy investment for any application.