Introduction

Load cells play a crucial role in a wide range of industries, from manufacturing and transportation to healthcare and agriculture. These devices measure force or weight with high accuracy, providing essential data for safe and efficient operations. In this article, we’ll explore the top applications of load cells in both industrial and commercial environments, emphasizing their importance and versatility.

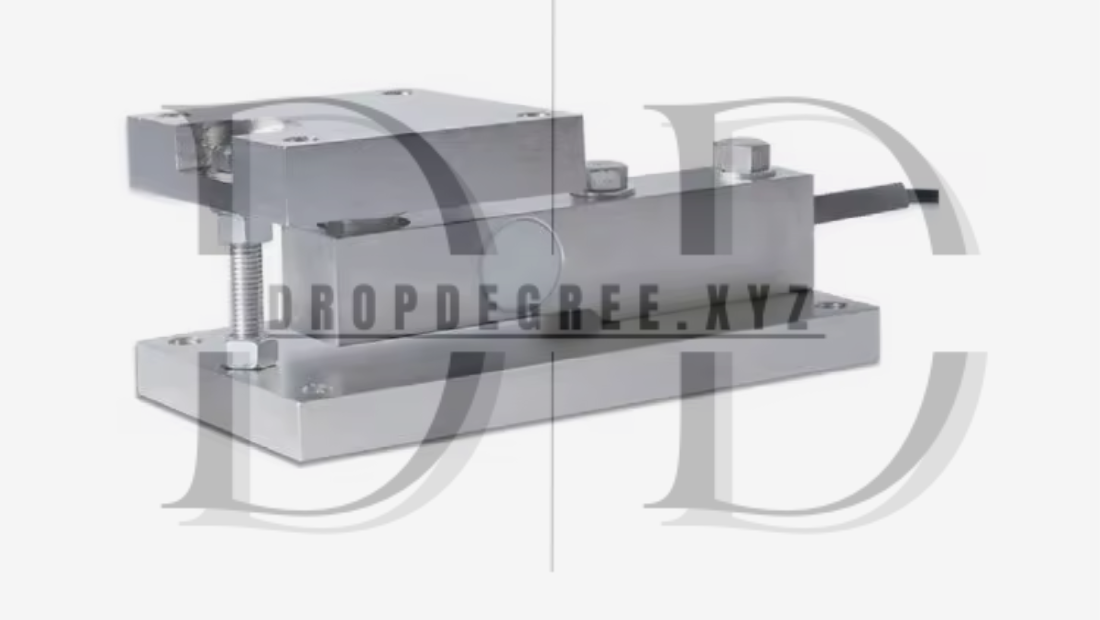

What is a Load Cell?

A load cell is a transducer that converts force into an electrical signal. Load cells are typically made of steel or aluminum and contain strain gauges that respond to force by altering electrical resistance. This change is then converted into a readable weight measurement, which can be used for everything from ensuring product quality to enabling precise dosing in medical applications.

Industrial Applications of Load Cells

1. Weighing and Batching Systems

In industries such as food processing, pharmaceuticals, and chemicals, weighing and batching systems are critical for maintaining consistency and quality. Load cells ensure precise weight measurements in these systems, allowing for accurate dosing and mixing of ingredients. This level of control is crucial for complying with safety standards and meeting product specifications.

2. Tension Measurement in Manufacturing

In the manufacturing sector, especially in the production of textiles, paper, and metals, maintaining optimal tension in materials is essential. Load cells monitor and control tension by measuring the force exerted on materials during processes like winding, unwinding, and cutting. This application not only enhances product quality but also prevents machine wear and tear, reducing maintenance costs.

3. Overload Protection in Cranes and Lifting Equipment

Safety is paramount in industries that rely on heavy lifting, such as construction and logistics. Load cells are embedded in cranes, hoists, and other lifting equipment to measure load weights and prevent overloading. By signaling an alert when weight exceeds safe limits, load cells help avoid accidents, protect equipment, and ensure worker safety.

4. Force Measurement in Assembly Lines

Automated assembly lines in the automotive, electronics, and consumer goods industries use load cells to measure force during assembly processes. Load cells ensure that parts are assembled with the correct force, which is vital for product durability and quality. This application improves assembly accuracy, reducing the chances of product failure and costly recalls.

Commercial Applications of Load Cells

5. Retail and E-commerce Weighing Solutions

Load cells are at the core of retail weighing scales used in supermarkets and stores. From weighing fresh produce to calculating parcel weights for shipping, these scales ensure that customers are charged accurately and that packages meet shipping requirements. For e-commerce businesses, load cells are crucial for logistics, helping with precise weight measurement of packages and cost-effective shipping.

6. Medical and Healthcare Applications

In the healthcare sector, load cells are used in medical devices that measure patient weight, such as hospital beds, dialysis machines, and infusion pumps. Accurate weight data is essential for patient care, particularly for dosing medication and monitoring health conditions. Load cells ensure precise measurements, which directly impact patient safety and treatment efficacy.

7. Agriculture and Livestock Weighing Systems

Load cells play an important role in agriculture, particularly in weighing livestock and measuring the output of farming equipment. Farmers use load cell-powered systems to weigh animals, which aids in monitoring their health and growth. Load cells are also used in weighing feed and fertilizers, optimizing their distribution for better productivity.

8. Logistics and Freight Management

In logistics, accurate weight measurements are vital for optimizing load capacities and ensuring safety regulations are met. Load cells are used in weighbridges and truck scales to measure vehicle weights, preventing overloading and complying with transportation laws. This application improves operational efficiency and reduces the risk of fines or penalties.

Specialized Load Cell Applications

9. Aerospace Testing and Development

In the aerospace industry, load cells are critical for testing the structural integrity of aircraft components. Load cells measure the stress and force on materials and components, ensuring that they can withstand extreme conditions. This application is essential for safety and reliability, as load cells provide accurate data that helps engineers design and test aircraft more effectively.

10. Robotics and Automation

With the rise of automation and robotics in manufacturing, load cells have become indispensable for force measurement and control. Load cells help robots apply the right amount of pressure, enabling them to handle delicate parts without causing damage. This application enhances the functionality and flexibility of robotic systems, paving the way for more complex tasks.

11. Oil and Gas Industry Applications

Load cells are widely used in the oil and gas industry for measuring force and weight in drilling rigs, pipelines, and storage tanks. Load cells monitor equipment loads, detecting early signs of stress or wear. This application is crucial for safety, as load cells help prevent equipment failures and ensure safe operation in high-risk environments.

The Benefits of Load Cells Across Industries

Accuracy and Precision

One of the main advantages of load cells is their high level of accuracy. This precision is invaluable across industries, whether for ensuring fair pricing in retail or safe load handling in construction. By delivering consistent and reliable data, load cells support quality control and compliance with industry standards.

Durability and Reliability

Industrial-grade load cells are built to withstand harsh conditions, making them ideal for challenging environments like factories, construction sites, and oil rigs. With features like overload protection and waterproofing, these load cells provide reliable performance and long service life, reducing the need for frequent replacements.

Improved Efficiency and Cost Savings

By providing real-time data, load cells enable better decision-making and process control. Industries benefit from optimized operations, reduced downtime, and minimized waste, leading to significant cost savings. Load cells also help prevent costly errors, such as overloading in logistics or incorrect batching in food production.

Choosing the Right Load Cell for Your Application

Selecting the appropriate load cell for a specific application depends on factors like load range, accuracy requirements, and environmental conditions. Here are some tips for choosing the right load cell:

- Determine the Load Capacity: Choose a load cell that can handle the expected weight or force, with a safety margin to prevent overload.

- Consider Environmental Conditions: For applications exposed to dust, moisture, or extreme temperatures, look for load cells with protective coatings and IP-rated enclosures.

- Check for Calibration and Certification: Ensure the load cell meets industry standards for accuracy and reliability. Some applications may require NIST-traceable or ISO-certified load cells for compliance.

- Evaluate Connectivity Options: Many modern load cells offer digital outputs for easy integration with control systems, data logging, or remote monitoring.

Future Trends in Load Cell Technology

As industries increasingly adopt automation and the Internet of Things (IoT), load cell technology continues to evolve. Emerging trends include:

- Wireless Load Cells: Wireless connectivity allows for remote data monitoring and reduces installation complexity, especially in hard-to-reach areas.

- Miniaturized Load Cells: Smaller load cells are gaining popularity in applications with limited space, such as medical devices and robotics.

- Smart Load Cells: Equipped with self-diagnostic features, smart load cells can detect errors and predict maintenance needs, enhancing operational efficiency.

Conclusion

Load cells are indispensable components in both industrial and commercial settings, providing accurate and reliable measurements that power a vast range of applications. From improving quality control in manufacturing to ensuring safety in healthcare and logistics, load cells offer countless benefits. By choosing the right load cell and leveraging its full potential, businesses can achieve enhanced productivity, cost savings, and operational efficiency.

Whether you’re in manufacturing, healthcare, or agriculture, load cells are integral to optimizing performance and ensuring safety. Embrace this technology to keep your operations running smoothly and to stay competitive in an increasingly data-driven world.